by Stephen Miles, 1/1/2026, Ipswich Historical Society Board Member 1986-1989; President 1989-92; Member Ipswich Historical Commission

Richard Candee, Director of Preservation Studies at Boston University, presented a lecture on “The Industrial Heritage of the North Coast” on Sunday, February 9, 1986, at the Heard House (the Ipswich Museum), Main Street in Ipswich. This lecture was part of the “Winter Lecture Series,” a staple of the Society’s educational outreach during the decade. Highlights from the talk, as captured in the Ipswich Chronicle, focused on three core areas:

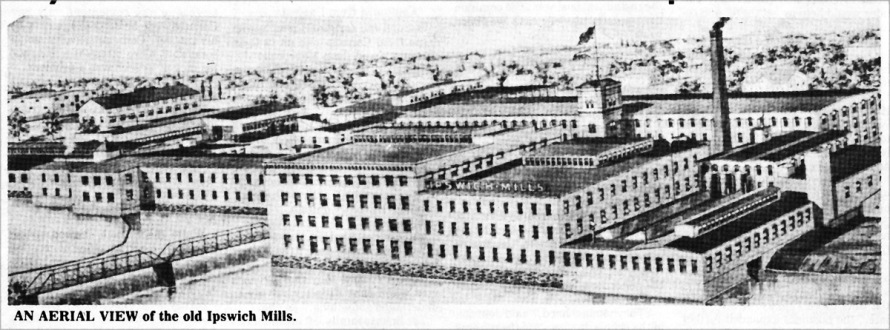

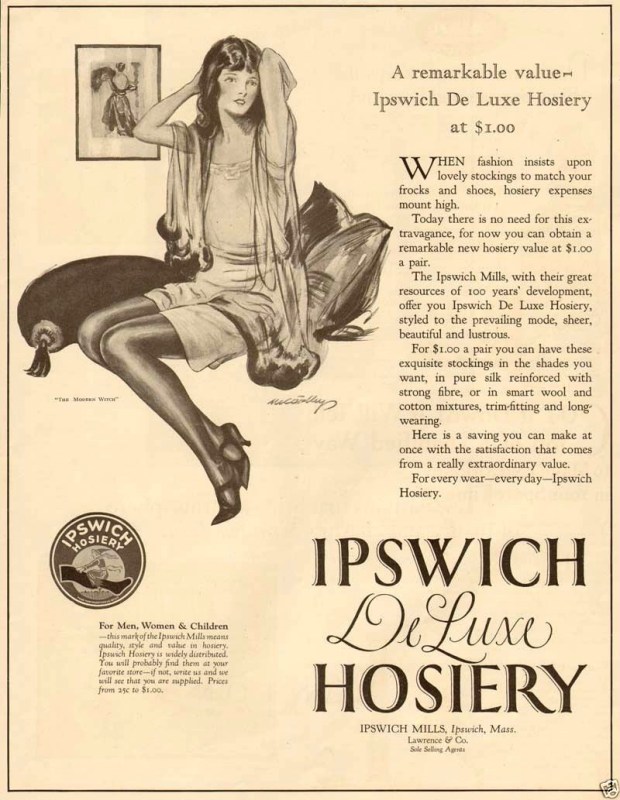

- The Rise of the Hosiery Industry: Candee detailed how Ipswich moved from a quiet agrarian town to a global leader in hosiery. He famously discussed the “Lace Schools” and how the Ipswich Mills (at the dam on the Ipswich River) represented a shift from traditional craftsmanship to industrial power.

- Architectural Significance of the Mills: He argued that the brick mill structures were as architecturally significant as the Whipple House, urging the town to consider “industrial preservation” as a formal goal.

- Worker Housing: He highlighted the “mill tenements” and the “Pole Alley” area, explaining that these structures were a deliberate part of the town’s social fabric, not just “utilitarian” buildings.

Following the success of his February lecture, Professor Candee returned in May to lead a walking tour titled “Ipswich’s Industrial Landscape.” This tour included a visit to the Ipswich Mill complex, an analysis of the Choate Bridge (the oldest double stone arch bridge in the country), and a discussion of the Heard House as the residence of a family whose wealth was tied to these same industries.

This specific lecture is cited by local historians as the catalyst for the Ipswich Historical Commission’s increased focus on the 19th-century history of the town. It moved the “historical” boundary of the town forward, acknowledging that history didn’t end in the 1700s. It was built on prior research by the Ipswich Historical Society curator, Elizabeth Newton’s interest in the lace trade and local historians, including Scott Coles, “It Was Usually Boom or Bust for Ipswich Mills.” [Ipswich Chronicle Thursday July 5, 1984 p70 ]. This lecture on “The Industrial Heritage of the North Coast” was part of a series of regional tours and seminars that Candee led or co-organized. At the time, Candee was a national officer of the SIA and the Director of Preservation Studies at Boston University.

While Ipswich was famous for its “First Period” houses, Candee challenged the Historical Society to recognize the Ipswich Mills (the hosiery and lace industry) as a vital part of the town’s architectural legacy. He drew parallels between the housing in Ipswich and his research on Atlantic Heights (published in 1985), explaining how “Company Town Model” worker housing was a deliberate architectural choice by industrial owners. He further discussed the history of machine knitting in New England, specifically how British technology transfer and immigrants (lace makers) transformed the economy of Ipswich.

- The Introduction of the Hosiery Glove and Shawl Industry into the United States and its Early Development: This work is fundamental to understanding the specialized textile industry of Ipswich. Candee explores how British “hand-frame” technology was smuggled into New England, leading to the establishment of the Ipswich Mills as a global leader in hosiery.

- Industrial Survey Work: In the late 1960s and 70s, Candee worked with Old Sturbridge Village and the Save the Mills Society. He was instrumental in documenting the architectural significance of New England mill buildings, advocating for their inclusion in the National Register of Historic Places to prevent their demolition.

- “Atlantic Heights: A World War I Shipbuilders’ Community“: While focused on 1918 Portsmouth, this book is his most famous exploration of early 20th-century industrial living and worker housing, themes that parallel the “mill girl” and immigrant worker housing found in Ipswich.

Candee’s research highlights the following trends affecting the Ipswich Mills in the early 1900s:

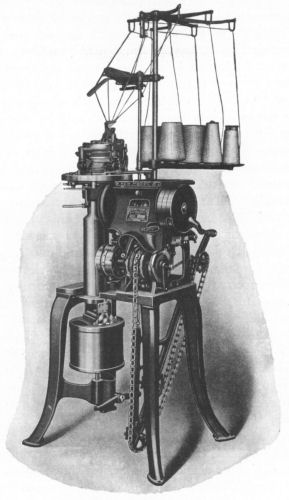

- Technological Shift: The transition from manual “hand-frame” knitting to the high-speed circular knitting machines that made Ipswich the “Hosiery Capital of the World.”

- The 1913 Strike: His work often touches upon the social history of these spaces, including the 1913 IWW (Industrial Workers of the World) strike at Ipswich Mills, which was a pivotal moment for labor rights in the region.

- Architectural Preservation: Candee emphasized that the Ipswich Mills were not just factories but “industrial monuments” that shaped the entire layout of the town, from the workers’ tenements to the mill owners’ estates.

Here is an excerpt from Richard Candee’s study of first period textile mills in New England that preceded the period covered in the lecture at the Ipswich Historical Society when the first fully machine made stockings at the Ipswich Mills were made using licensed UK patented technology that scaled, displacing the thousands of home workers who were knitting on the heels and toes of socks across New England and led to the takeover of Lawrence and Lowell mills leading up to contracts to supply the armed forces in WWI:

“Watching stockings, drawers, and shirts make themselves.“

Portsmouth, N.H. and New England’s Knitting Industry, 1832 – 1875

Richard M. Candee, Boston University

“The first American to transform the mechanical operation of the stocking frame to rotary power, a prerequisite for factory use of water or steam power, was John Bazin Jr. (1792-1860). The son of a Huguenot emigre” from St. Helier on the Isle of Jersey, Bazin was a machinist at Canton, Massachusetts. His hand-cranked ‘stocking loom’, patented October 28, 1814, preceded by almost two decades all other known American attempts. This near-forgotten invention was used in a lace and handshop at Ipswich, Massachusetts, in the 1820s, where it was seen in 1830 by an anonymous English visitor after the company failed.

To a friend at home he wrote, “These two frames you would think a great curiosity; they are composed principally of wheels and pinions, and have hooks instead of needles, and on the rotary principle, and are calculated to do an immense deal of working in a very short time, but they will only make straight pairs, and they will work up cotton or worsted as fast as a boy will wind it. They are of Yankee invention, about 12 inches wide; I have seen one of them, but they are standing still.”

One investor in this hand cranked stocking factory written in 1834 described the inventor’s aspirations: “In June last I was was reminded of the existence of your old friend Bazin (of whom I had lost sight for a year or two past)” when Bazin sued for $3000 over breaking his contract, “whereby he was deprived of the ability to perfect his stocking machine & to travel with it in Europe a year or two at our expense” The firm’s failure destroyed Bazin’s hope of selling his invention.

Pepper also gave work to Portsmouth’s forgotten hosiery workers, the “large class of women and children called seamers.” From 1868 to 1871, he was the agent of A. A. Lawrence’s Ipswich Mills, the first corporation to successfully compete with English cotton hosiery. Circular stockings made at Ipswich Mills had feet of two parts, a sole and an instep. It was necessary to join these together along the sides and across the toes, as well as close the bottom of the leg!

Part of this work was done on looping machines at the mill, but the greater part was sent outside to be done by needlework. Much of this was sent to Portsmouth, New Hampshire, Eliot, and Biddeford, Maine, to be distributed among farmers’ wives and daughters.

By 1870, in New Hampshire alone, 13,000 women worked outside the factory knitting on the heels and toes, earning $1 per dozen for this work” while in Maine, New Hampshire and Vermont, “nearly the whole female population, within a radius of twenty miles” of a knitting mill could be seen at home finishing ‘goods partially fabricated by machinery. “

Bibliography:

- The Hosiery Industry of Ipswich, 1822-1922; Portsmouth Journal, 20 May, 1871; [Boston] Ipswich Mills, 1922: 18.

- “The Industrial Heritage of the North Coast” (1986): Candee co-authored a guide for the Society for Industrial Archeology. He was one of the first to argue that the workers’ housing in the mill district was as historically important as the “Great Houses” of the first settlers in Ipswich. Further, Candee explored how British “hand-frame” technology was smuggled into New England, leading to the establishment of the Ipswich Mills as a global leader in hosiery.

- SIA New England Chapter Newsletters (1986): Richard Candee is recorded leading tours of “rehabilitated mills” and “shipbuilding company complexes” across the North Shore and Southern New Hampshire during this year.

- “Writings on New England History;” Additions to the Bibliographies of New England History Series (to 2001) Volume 10; Committee for a New England Bibliography; Roger Parks, Editor; Massachusetts Historical Society; 2003 – A bibliography that tracks Richard Candee 1986 contributions specifically regarding the “Lace schools and lace factories” of the New England coast. Internet Archive 2016.

- “Domestic Industry in the Factory Age: Anglo-American Development of the ‘Family’ Knitting Machine,” and “Lace Schools and Lace Factories: Female Outwork in New England’s Machine-Lace Industry, 1818-1838.” Candee, Richard. Textile History 29, no. 1 (Spring 1998): 62-92.

- “British Framework Knitters in New England: Technology Transfer and Machine Knitting in America, 1820–1900” (Textile History, 2000): This is the core scholarly article detailing how British workers brought knitting frames to Ipswich. It explains why Ipswich became the center of the industry before the 1900s boom. “The framework knitter was the pioneer of the American hosiery industry, and Ipswich was his most successful frontier.”

- “Lace Schools and Lace Factories: Female Outwork in New England’s Machine-Lace Industry, 1818–1838” (in Textiles in Early New England, 1999): While it focuses on an earlier period, Candee uses this to establish the “pre-history” of the Ipswich Mills, showing how the local female workforce was already highly skilled in fine textile work before the 1900s industrialization.

- The Hand-cranked Knitter and Sock Machine: A Social History and Catalogue of 19th and 20th Century Home Knitters of American Invention; Richard M. Candee, Candlewood Press, 2005. A book resulting from his Smithsonian fellowship. It details the mechanical evolution of the circular knitting machines that filled the Ipswich Mills in the early 1900s.

Further Reading

- Wikipedia: Ipswich Lace

- The Project Gutenberg eBook of Textiles, for Commercial, Industrial, and Domestic Arts Schools

- Fine Thread, Lace, and Hosiery, a paper read before the Historical Society of Ipswich, April 13, 1903, by Jesse Fewkes

- Ipswich Mills and Factories

- Ipswich Hosiery