Inventory No: IPS.9009: Ipswich Mills Hosiery Manufacturing Company Dam. Survey Form F (structure) submitted to the Massachusetts Historical Commission, Recorded by: Ted Dattilo for the Public Archaeology Laboratory, Inc., May 2024. Received by the Mass. Historical Commission on Nov. 12, 2024

- Year Constructed: 1908; Architect: Stickney, Stephen A. Company

- Recommended for listing in the National Register of Historic Places? Answer: No

Historical Narrative: The history of the dam and how it relates to the development of the community

The Town-owned Ipswich Mills Dam is run-of-the-river at the head of tide on the Ipswich River in downtown Ipswich, approximately 750 ft south (upstream) of the Route 133/South Main Street/Choate Bridge crossing. The dam is the first manufactured fish passage barrier moving inland up the Ipswich River from Ipswich Bay. It was built on or just downstream of a natural rock ledge outcrop or small rock rapids (locally referred to as the Upper Falls) on the river. The elevation of competent bedrock ledge at the dam site is not known below the depth of the riverbed cobbles and boulders visible at low tide. (The locally called Lower Falls is an existing rock rapids section of the river approximately 1,200 ft downstream, just below the County Road bridge.)

The dam’s cut granite block and concrete spillway extends 132 ft across most of the width of the river channel in downtown Ipswich. A concrete deck pedestrian footbridge across the river is just downstream of the spillway. The west bank of the dam(river left) has a paved municipal parking lot and viewing area, and a concrete and stone retaining wall. The EBSCO Publishing building and foundation are immediately upstream of the dam, south of the parking lot and viewing area. The east bank of the dam (river right) has two concrete fish ladders (one active and one abandoned) immediately downstream of the dam, along with a viewing ramp. The dam was constructed to increase the head of the Ipswich River and allow water to flow freely over the spillway during most flow levels. Because of this, the dam’s impoundment has a minimal storage capacity. Behind the dam, the Ipswich River extends to the south.

A dam has existed at the Ipswich Mills site since at least 1637, and possibly as early as 1635, making it the earliest waterpower privilege to be developed on the Ipswich River by English settlers. The first dam at the site was built by Richard Saltonstall, who obtained exclusive rights to the privilege to power a grist mill. The dam was likely constructed of logs and stones at a series of natural waterfalls on the Ipswich River known as Upper Falls, which were approximately 30 ft upstream (south) of the current dam (Harris 2015; Stump 2011; Waters 1905:77).

Richard Saltonstall (1610–1694) was the son of Sir Richard Saltonstall (1586–1661), First Assistant to Governor Winthrop of the Massachusetts Bay Colony and a Patentee of Connecticut. Saltonstall graduated from Emmanuel College in Cambridge, England, in 1627 and accompanied his father to New England in 1630. He settled permanently in Ipswich in 1635 and was involved as a deputy at the court in the town. Over the course of the remainder of his life, he regularly travelled between Ipswich and England, where he died in 1694 (Saltonstall 1897:86–87).

Saltonstall’s grist mill remained the only one on the Ipswich River until 1687. The vicinity of the dam had become a nexus of early industrial activity by the end of the seventeenth century and was known as “Mill Garden” (Waters 1905:329) due to the presence of fulling mills, sawmills, woolen mills, bark mills, dye houses, tanneries, and other establishments at this and nearby mill privileges, including the Lower Falls. In 1729, the Saltonstall family divested themselves of their financial interest in the site, selling their interest in the mills and dam to John Waite, a clothier, and Samuel Dutch, a bricklayer. At that time, the dam powered a grist mill and fulling mill on the west bank of the Ipswich River, and a sawmill established by unknown persons on the east bank of the river.

Waite and Dutch sold their interests in the property a few years later, and it changed hands several times before being acquired by Michael and Nathaniel Farley by 1755. The fulling mill likely “went out of use as the hand weaving in the weavers’ shops all about the Town gave place to factories” (Waters 1905:329–330). By 1792, Asa Andrews was operating the sawmill as well as a scythe mill on the east side of the river (Harris 2015; Stone 1930:414; Stump 2011; Waters 1905:329) (see Figure 1). During the Farley’s involvement at the privilege, it was sometimes referred to as “Farley’s Falls” (Massachusetts General Court [MGC] 1832).

The Industrial Revolution that began in the late eighteenth century ushered in the next significant phase of development at the Ipswich Mills Dam, shifting milling at the site away from small-scale production for the local market toward manufacturing and additional markets In the early nineteenth century, George Washington Heard (1793–1863), a wealthy merchant in the China trade; his brother Augustine Heard (1785–1868); and their brother-in-law Joseph Farley became interested in establishing a lace industry in Ipswich. In 1822, the Heards and Farley convinced Benjamin Fewkes and George Warner to smuggle a lace machine (the first in the country) into Ipswich from England. Fewkes (1788–1869) and Warner were from Loughborough, England, and were skilled textile workers from the mechanized hosiery knitting and lace weaving trades.

In 1824, Joseph Farley and the Heard brothers opened the Boston & Ipswich Lace Company that operated in a shop on South Main Street near the dam and footbridge across the Ipswich River. There, the company produced lace until 1828, when it ceased operation, likely due to English trade interference and competition that made the industry less profitable. English interference in the nascent American lace industry culminated in heavy English tariffs on thread exported to the United States and put most lace-manufacturing operations out of business by 1834. The three partners began a new venture by chartering the Ipswich Manufacturing Company to produce cotton cloth (Fewkes 1938:43–53; Hartmann and Friedberg 1996:13–15; Hurd 1888:638; Stone 1930:414).

The Ipswich Manufacturing Company was chartered with $200,000 in capital in 1828 and was the first sizeable manufacturing corporation in Ipswich. The company expanded its cotton cloth production for several years, reaching 450,000 yards of cloth annually. Preparations for this new enterprise had begun in 1827, when Joseph Farley replaced the dam with a higher, more substantial stone dam. During construction of the new dam, Farley was given permission to “fill up the town [ford]way, as a watering-place” (Felt 1834:101), which was just below the dam (Harris 2015; Waters 1917:636). The new mill for the Ipswich Manufacturing Company was constructed of stone in 1828–1829. The mill, identified as a “cotton factory,” and also known as the “stone mill,” is depicted at the west bank of the river on the 1832 (Anderson) map of Ipswich, with the adjacent dam (see Figure 2 inset) (Anderson 1832; Felt 1834:101; Harris 2015; Hartmann and Friedberg 1996:15; Stone 1930:414).

In 1830, 12-inch flashboards were added to the dam to increase the size of the impoundment. From the 1830s through the 1850s, a regular series of compensations was made to local landowners by Augustine Heard for flood damage due to the dam. By 1836, the Ipswich Manufacturing Company had financial difficulties (Hartmann and Friedberg 1996:15; Stump 2011). In 1845, the Massachusetts General Court (MGC) passed legislation mandating that the Ipswich Manufacturing Company “construct…a good and sufficient passage-way for the fish to pass over said dam up Ipswich River” (MGC 1845).

During the industrial development of the west bank of the Ipswich River, the earlier sawmill on the east bank of the river continued to operate using the waterpower of the dam. By the 1830s, the sawmill was operated by Benjamin Hoyt. In 1843, Hoyt signed a 10-year lease with the Ipswich Manufacturing Company that granted him the rights to build a new sawmill at the site of the old sawmill and to use the waterpower at the site. About 1858, Hoyt’s sawmill building was purchased and moved several blocks away to 17 County Street (see Figure 3 inset; Harris 2015; Stump 2011; Waters 1905:637), where it remains today.

In 1846, the Ipswich Manufacturing Company sold the stone mill to the Dane Manufacturing Company, which continued to produce coarse cotton cloth known as “drilling.” The Heard family remained involved, with George W. Heard serving as president of the new company. The Ipswich Mills Dam was not included in this purchase and was still owned by Augustine Heard. The Dane Manufacturing Company manufactured cotton cloth at the stone mill until about 1868 (Figure 4; Waters 1917). In 1858, Heard had raised the flashboards on the dam from 12 to 18 inches, resulting in additional property damage upriver from the dam and commensurate compensation to local landowners from Heard (Adams 1856:69; Harris 2015; Hartmann and Friedberg 1996:15; Harvard Business School 2011; Stump 2011; Walling 1856).

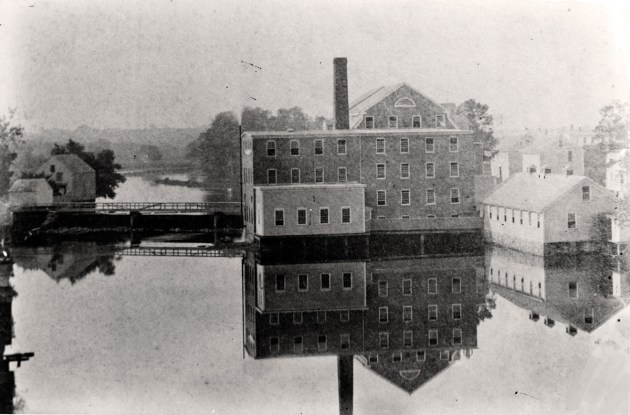

The Ipswich Mills site entered its next significant phase in 1868, when the property, presumably including the dam, was purchased by Amos A. Lawrence (1814–1886) for $70,000 and renamed The Ipswich Mills Company, which produced hosiery and became the “largest stocking mill in the country” (Stone 1930:414). Hosiery became an important industry in Ipswich, with three companies employing a total of 451 workers by 1880. Lawrence was heavily involved in the textile industry and was from

the prominent family for which Lawrence, Massachusetts, is named.

The Ipswich Mills complex expanded while it was owned by the well-capitalized Lawrence family. By 1872, several new structures were on the site, including the hosiery mill (Figure 5). According to Stump (2011), about 1880 the Ipswich Mills Dam may have been reconstructed in place based on the different shape of the dams shown on the 1872 (Beers) and 1884 (Walker) town maps and 1887 (Sanborn) insurance map, along with a different technique used to cut the stone and the different sizes used in its construction.

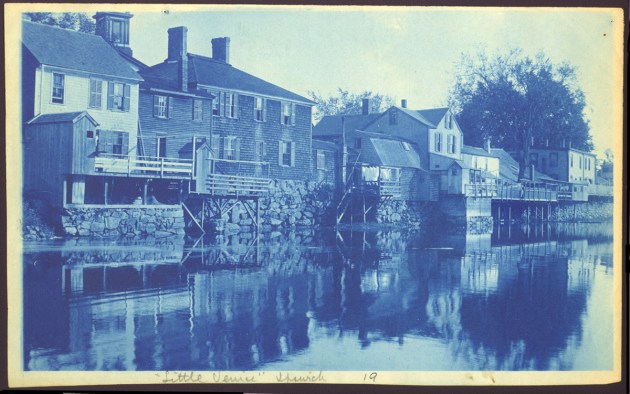

By 1884, the Ipswich Mills property contained nine buildings on the west bank of the Ipswich River and

adjacent to the dam known as the Ipswich Hosiery Mills (Figure 6). Between South Main Street and the east bank of the river downstream (north of) the dam, wood-frame buildings (unrelated to the Ipswich Mills) set on stone retaining walls and wood pilings lined the river. By 1887, a footbridge was built atop the dam structure. The area was known locally as “Little Venice” for its Italian immigrant population, working-class shops, single- and two-family residences, and mill tenements (Hartmann and

Friedberg 1996; Sanborn 1887, 1892, 1897, and 1902; Stone 1930; Stump 2011).

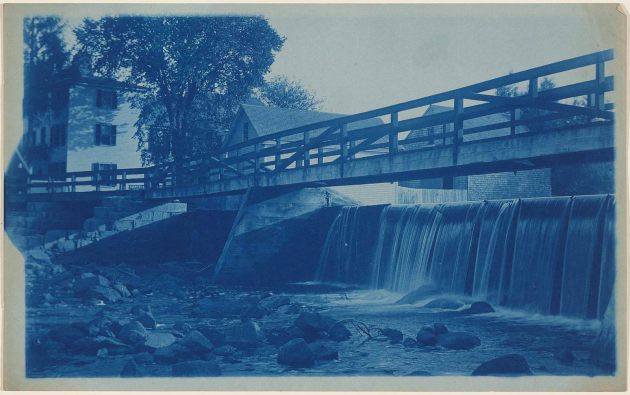

Late nineteenth-century photographs and insurance plans show that the ca. 1880 Ipswich Mills Dam was a stone masonry structure with a distinctive “dog-leg” footprint. The western two-thirds or three-quarters of the structure ran on a northwest–southeast footprint. The eastern section and end of the structure ran almost due east–west (Figure 7) (Associated Mutual Insurance Companies 1904; Sanborn 1887, 1892, 1897). Several piers of indeterminate construction extended laterally and above the spillway and supported the wood footbridge (Figures 8 and 9). A fishway to allow for passage of alewives had been

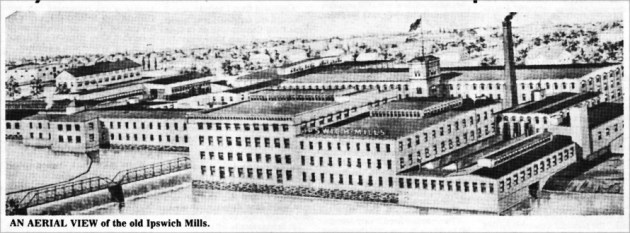

installed at the east side of the dam in the 1880s (Belding 1920). In 1908, Ipswich Mills was expanded as the company entered a period of prosperity. Considerable construction at the mill site included demolition of the 1829 stone mill to make way for a new knitting mill (no longer extant), which was adjacent to the dam on the west bank of the Ipswich River. Ipswich Mills also owned two small wood buildings, possibly worker housing, adjacent to and upstream of the dam on the east bank of the river (Sanborn 1907, 1916; Walker 1910).

Ipswich Mills reached its peak in prosperity and productivity during World War I, with strong demand for its products from U.S. and Allied forces in Europe and rising domestic demand. The company was reportedly the largest hosiery manufacturer in the world from 1916 to 1919 (Harris 2015; Hartmann and Friedberg 1996; Stump 2011). The dam was reportedly rebuilt in 1908; according to Stump (2011), this work was presumably done to increase or improve the reliability of the available waterpower. A 1912 dam inspection report also indicates that the dam structure was “rebuilt in 1908.” The 1912 report further notes that the dam was in good condition and constructed of “coarsed [sic] stone masonry with timber flash-boards,” and that recent repairs consisted of putting in “one new gate and pointing a few joints” (ACOE 1980).

In addition, a 1925 dam inspection report indicates that the dam was of “cut granite on the face,” and the owner had a “plan of it on file in their office drawn by Charles T. Hain when the structure was rebuilt about 1908.” That plan shows a rock foundation beneath the dam

(ACOE 1980). A comparison of insurance plans before (Sanborn 1892, 1897, 1902, and 1907) and after 1908 (Sanborn 1916, 1929, and 1944) supports the dam rebuild during that year. These plans indicate that the dam footprint was realigned at its southeast end, eliminating the “dog leg” that had previously existed (Figures 10 and 11). The dam’s location also appears to have been shifted slightly to the north (downstream), which would also explain the elimination of the “dog leg” on the east side. To further support a 1908 rebuilding of the dam, an 1896 photograph shows masonry buttresses on the downstream side (see Figure 9) that are not seen in later photographs or during PAL’s walkover survey.

Low water conditions during August 2016 exposed what appeared to be the stone remains of an earlier dam at the location depicted on the (Sanborn) insurance maps before 1908. The 1916 (Sanborn) insurance map confirms that the dam had a footbridge over it at that time (see Figure 11), which is likely the steel truss structure that appears in a mid-twentieth-century photograph of the dam and mill site (Ipswich Library photograph collection). The 1880s fishway at the dam reportedly was destroyed in 1916, and a new fishway was installed at the same location (east side of the dam) in 1919 in an effort by Massachusetts’ Division of Fisheries and Game to re-establish the fishery (Belding 1920). The 1912 dam inspection report notes that the dam included a “fish run on the east side” and the 1925 inspection report mentions that the “fish-way has recently been built,” presumably the replacement one installed in 1919 (ACOE 1980).

After World War I, Ipswich Mills experienced a rapid decline, with a 50% slowdown in production in late 1920 due to consumer demand for higher-grade hosiery than the dated circular cotton stockings that were being produced. Ipswich Mills also faced increased competition, evidenced by the organization of the Hayward Hosiery Company in Ipswich in 1922. The Ipswich Mills Company ceased operation in 1928, and the machinery was sold to mills in Moscow, Russia (Hartmann and Friedberg 1996:21; Sanborn 1929; Stone 1930:414; Stump 2011). The 1930 dam inspection report indicates that the mills were closed, and the machinery had been sold, and “from all appearances there have been no changes since the last inspection [in 1928], and the dam seems to be in good condition” (ACOE 1980).

The Ipswich Mills complex sat empty until Ernest Currier purchased it for $13,000 for unknown uses in 1932. The 1932 dam inspection report indicates that the dam was in “good condition” and there had been no change, and the 1934 inspection report notes that the dam belonged to E. B. Currier, Real Estate Agent, and again it was in “good condition” and there had been no change. That report also includes “The waterpower is used occasionally. There is a watchman on duty all the time. Water is

flowing over the dam today.”

The 1936 dam inspection report indicates that the dam was then owned by the Tanning Process Company, a subsidiary of United Shoe Machinery Company (USMC). The tanning company used the dam for power when there was sufficient water, and there was “some leakage around the old gates.” The 1936 report also notes that the owner intended to repair the “old gates and stop all leaks” within the following year, and that he would “probably build a dike upriver to hold out the water while making

repairs.” It is not clear if these repairs were made, since the 1938 dam inspection report still notes that “some of the timber gates need repairing.” The 1938 report also makes note of a “concrete wall at the westerly end of the dam.” The October 1940 dam inspection report indicates that “new gates and timber work have just been built at the westerly end of the dam, where the wheels are. Last year, new draw-off gates were built at the easterly end of the dam…and the dam is in good condition” (ACOE

1980).

According to dam inspection reports, from 1940 to 1948 Hygrade Sylvania Corporation (Sylvania) leased part of the “old mills” from the USMC to produce products such as “proximity fuzes, military and commercial transformers as well as tungsten coils” (ACOE 1980; Stump 2011). During World War II, Sylvania participated in then-secret war work for the US Navy and employed 1,200 workers to build proximity fuzes that aided in the Allied victory. The dam was maintained by the USMC and used by Sylvania to supply waterpower for its machinery (Figure 12).

The 1942 dam inspection report notes that there was a “slight seepage at the easterly end of the dam at the fishway” but that it was otherwise in good condition with “water flowing over the flashboards which have been renewed since the last [October 1940] inspection.” The 1944 dam inspection report indicates that the only repair made since 1940 was the re-planking of the floor of the footbridge over the spillway. No leaks were observed, but the “hoisting machinery of one of the gates needs to be repaired” (ACOE 1980). In 1946, the dam inspection report indicates that “new timbers have been placed under east gates. The center pier of the bridge has been braced with timbers,” and the condition of the dam was the same as indicated in the 1944 report.

By 1948, Sylvania Electric Products, Inc. had taken over ownership of the mill property, including the dam, and the inspection conducted that October noted “leaks under spillway at westerly end” and disintegration in the concrete in the fishway (ACOE 1980). In 1950, the dam inspection report notes that the leaks at the west end of the spillway were still “very bad” although some work had been done on the gates. The concrete sidewall of the fishway was also still “badly disintegrated.” The 1952 dam inspection report notes that the owner attempted to stop the leakage at the west end of the dam by backfilling the back of the dam with gravel, but the leakage continued. In 1954, no repairs had been made to the dam, although the inspection report notes that the owner was cooperating to keep it a “safe structure.” The dam inspection reports in 1956, 1958, and 1959 indicate the same dam conditions, and that the owner continued to cooperate by keeping the dam “under constant observation to keep the structure safe.”

In 1961, all gates were reported to be closed except for the fishway, which was kept open; in 1962, the fishway was “kept about halfway open” (ACOE 1980). The 1962 dam inspection report indicates continued leakage, and that the owners had arranged for a contractor to “gunite the face of the dam and the fishway, and backfill with impervious material the back of the dam near the mill” during the summer at low water (ACOE 1980). No other details about these repairs are in the available dam inspection reports, although there are recollections that the 1960s work may have involved an unconfirmed rebuild of the entire dam (Dick Dunn quoted in Stump 2011). A vertical slab of concrete lining the upstream face of the dam and exposed during drawdown in the summer of 2016 may date to this period of dam repairs and/or rebuild. Dam inspection reports in 1964, 1966, and 1968 indicate the dam conditions were good, with no mention of repairs or rebuilding (ACOE 1980).

The 1971 dam inspection report does not mention any particular issues with the dam. The next inspection, conducted on September 18, 1973, notes that the owner, then GTE Sylvania Inc., wanted to close all spillway and sluiceway openings. Also at that time, two of the gates on the east end of the dam appeared operable, but all others were inoperable. The 1973 dam inspection report also indicates that the owner was in the process of removing the steel truss footbridge supported by granite piers over the dam spillway (ACOE 1980).

On September 28, 1973, GTE Sylvania Inc. filed construction drawings and specifications with the Commonwealth of Massachusetts, Department of Public Works, Division of Waterways to undertake a series of alterations to the dam structure: removing the slide gates on the east and west sides of the dam and closing the openings; and closing the opening in the building foundation walls, where water flows from the west slide gates. By filling in the openings of the inoperable gates, the owners

hoped to eliminate leakages and create a continuous flow of water over the spillway crest, which would enhance the appearance of the dam. The state application to alter the dam also reported that the dam was constructed entirely of granite blocks with a 185-ft-long spillway that extended the full width of the river channel. The application does not mention concrete as a material used in the dam and spillway structures. No changes were proposed for the fish ladder at the east side of the dam. The dam alterations were approved by the Commonwealth of Massachusetts Department of Public Works, Division of Waterways on October 17, 1973.

GTE Sylvania Inc. began the work at the Ipswich Mills Dam on or about September 23, 1974. All the work was completed by December 27, 1974, except for an alternate concrete wall planned at the east slide gates that was not implemented due to the high-quality of foundation material found at this location (ACOE 1980). Stephen Stickney, current owner of the Stephen A. Stickney Co. of Boxford, Massachusetts, confirmed that his company did the work in the 1970s and that they would have used concrete masonry blocks to fill in the gate opening because they had never done concrete formwork (Daly and Cherau 2017). In addition to the dam alterations in 1973–1974, GTE Sylvania Inc. demolished

approximately 50%of the Ipswich Mills complex, including the machine shop and the knitting mill adjacent to the dam. The Town of Ipswich purchased the dam from GTE Sylvania, Inc. in 1982.

The February 4, 1993, dam inspection report indicates a 1900 date of original construction with modifications in 1908, and that the approximately 180-foot-long, and 9 ft-high structure was made of granite blocks. The report notes four low-level outlets and one mid-level outlet at the dam’s right abutment, but no gates, with the openings having been “blocked off with masonry products,” which corresponds to the personal account of the work undertaken by Stephen A. Stickney Co. in the 1970s. The 1993 report also mentions the presence of a 70- to 80-ft-long concrete fish ladder (constructed over a cut stone foundation) at the right abutment of the dam. Inflow to the ladder was via an opening through the granite outlet pier where the ladder joins the dam, but no gate to control flows through the fish ladder existed. The report also notes that the fish ladder was likely the one noted in dam safety files as having been built in 1925, and that the history of the structure’s functionality was unknown, but that it “had not functioned properly for many years” (Massachusetts Office of Dam Safety 1993).

No original construction drawings for the dam are on file at the Office of Dam Safety. Osram Sylvania sold the remaining Ipswich Mills buildings to EBSCO Publishing in 1995 (present EBSCO Information Services), which rehabilitated the mills in 1996 (Harris 2015; Hartmann and Friedberg 1996; Newton et al. 2001; Stump 2011). EBSCO Information Services continues to occupy the rehabilitated mill buildings today.

BIBLIOGRAPHY and/or REFERENCES

- Adams, George 1856 The Massachusetts Business Directory, for the Year 1856. Published by the Author, Boston, MA.

- Anderson, Philander 1832 Map of the Town of Ipswich, County of Essex, State of Massachusetts.

- Annin, Smith, & Co., Boston, MA. 1832b Plan of Ipswich Village.

- Army Corps of Engineers (ACOE) 1980 Phase I Inspection Report, National Dam Inspection Program, Ipswich River Basin, Ipswich, Massachusetts, Ipswich Mills Dam MA. 231, Low Hazard Dam. November 1980. Includes Compilation of State Dam Inspection Reports from 1912 to 1980. Department of the Army, New England Division, Corps of Engineers, Waltham, MA.

- Associated Mutual Insurance Companies 1904 Ipswich Mills, Spinning & Knitting Mill, Ipswich, Mass. Index No. 1432. Surveyed November 14, 1904.Associated Mutual Insurance Companies, Boston, MA.

- Beers, D. G. 1872 Atlas of Essex County, Massachusetts. D. G. Beers & Co., Philadelphia, PA.

- Belding, David L. 1920 The Commonwealth of Massachusetts: A Report Upon the Alewife Fisheries of Massachusetts. Prepared by the Division of Fisheries and Game, Department of Conservation, Boston, MA.

- Daly, John, and Suzanne Cherau: 2017 Cultural Resources Summary, Ipswich Mills Dam Removal – Feasibility Study, Ipswich, Massachusetts. The Public Archaeology Laboratory, Inc. Report No. 3193. Submitted to Horsley Witten Group, Sandwich, MA.

- Dodge, Barnabas 1794 A Plan of the Town of Ipswich in the County of Essex. On file, Massachusetts State Archives, Boston, MA.

- Felt, Joseph B. 1834 History of Ipswich, Essex, and Hamilton. C. Folsom, Cambridge, MA.

- Fewkes, Ernest E. 1938 Part II, of the Fewkes Genealogy: Giving an Account of Benjamin Fewkes of Loughborough and of Ipswich, Mass. and His Descendants in New England. Typescript Manuscript, on file at Ipswich Public Library, Ipswich, MA.

- Harris, Gordon: 2015 A Photographic History of the Ipswich Mills Dam. Electronic document,

https://historicipswich.net/2015/06/09/a-photographic-history-of-the-ipswich-mills-dam/, accessed April 7, 2016. - Hartmann, Lisa, and Betsy Friedberg: 1996 Ipswich Mills Historic District, Ipswich, MA. National Register of Historic Places Nomination Form. On file, Massachusetts Historical Commission, Boston, MA. Harvard Business School 2011

- Heard Family. Heard Family Business Records, 1734–1901: A Finding Aid. Electronic resource,

https://hollisarchives.lib.harvard.edu/repositories/11/archival_objects/109564, accessed March 2024. - Hurd, D. Hamilton, ed. 1888 History of Essex County, Massachusetts. Vols. 1-2. J. W. Lewis & Co., Philadelphia, PA.

- Massachusetts Office of Dam Safety, Department of Environmental Management 1993 Dam Inspection Report, Ipswich Mills Dam, Dam No. 5-5-144-4. February 4, 1993. On file, Massachusetts Office of Dam Safety, West Boylston, MA.

- Massachusetts General Court (MGC) 1832 Chapter 31–An Act to empower the “Ipswich Manufacturing Company” to construct a canal in Ipswich. Acts of 1832:212–213.

- 1845 Chapter 79–An Act relating to the Fishery in Ipswich River. Acts of 1845:427–428.

- Newton, Elizabeth H., Alice Keenan, Mary P. Conley: 2001 Over Three Hundred and Fifty Years of Ipswich History. Reprinted from 1984 Edition. The Three Hundred and Fiftieth Anniversary Committee of the Town of Ipswich, Ipswich, MA.

- Saltonstall, Richard M.: 1897 Ancestry and Descendants of Sir Richard Saltonstall, First Associate of the Massachusetts Bay Colony and Patentee of Connecticut. The Riverside Press, Cambridge, MA.

- Sanborn Map Company (Sanborn)

- 1887 Insurance Maps of Ipswich, Massachusetts. Sheet 3. New York, NY

- 1892 Insurance Maps of Ipswich, Massachusetts. Sheet 4. New York, NY.

- 1897 Insurance Maps of Ipswich, Massachusetts. Sheet 3. New York, NY.

- 1902 Insurance Maps of Ipswich, Massachusetts. Sheet 5. New York, NY.

- 1907 Insurance Maps of Ipswich, Massachusetts. Sheet 8. New York, NY.

- 1916 Insurance Maps of Ipswich, Massachusetts. Sheets 5–8. New York, NY.

1929 Insurance Maps of Ipswich, Massachusetts. Sheets 5–8. New York, NY.

1944 Insurance Maps of Ipswich, Massachusetts. Sheets 5–8. New York, NY.

- Stone, Orra L. 1930 History of Massachusetts Industries. Vol. 1. The S. J. Clarke Publishing Co., Boston, MA.

- Stump, John: 2011 Origins and History of the EBSCO Dam. Typescript Manuscript, on file, Ipswich Historical Society, Ipswich, MA., reproduced in A Photographic History of the Ipswich Mills Dam, by Gordon Harris 2024. Electronic document, https://historicipswich.net/2021/03/07/a-photographic-history-of-the-ipswich-mills-dam/.

- Walker, George H. 1884 Atlas of Essex County, Massachusetts. Geo. H. Walker & Co., Boston, MA.

1910 Atlas of the Towns of Topsfield, Ipswich, Essex, Hamilton and Wenham, Essex County, Massachusetts. Walker Lithograph & Publishing Co., Boston, MA. - Walling, H. F. 1856 A Topographical Map of Essex County. Boston, MA.

- Waters, Thomas Franklin: 1905 Ipswich in the Massachusetts Bay Colony, Volume I, A History of the Town From 1633 to 1700. The Ipswich Historical Society, Ipswich, MA. 1917 Ipswich in the Massachusetts Bay Colony, Volume II, A History of the Town From 1700 to 1917. The Ipswich

Historical Society, Ipswich, MA. - View Photos and Figures below in the lower half of Form F 9009

- Photo 1. Showing the Ipswich Mills Dam, view southwest.

- Photo 2. Showing the abandoned (1921) and active Ipswich Mills Dam fish ladders, view south. Photo 3. Showing the granite block and concrete masonry of the Ipswich Mills Dam, view south.

- Photo 4. Viewing platform on the east abutment of the Ipswich Mills Dam, view west.

- Photo 5. The impounded Ipswich River behind the Ipswich Mills Dam, view southwest.

Photo 6. Crest of the Ipswich Mills Dam, view west. - Photo 7. Downstream view of the Riverwalk Pedestrian Bridge and Ipswich River, view north.

- Photo 8. Ipswich Mills Dam, view east.

- Photo 9. Ipswich Mills Dam, view southeast.

- Photo 10. Seating area on the west abutment of the Ipswich Mills Dam, view south.

- Figure 1. Showing the location of the Ipswich Mills Dam on the 1794 (Dodge) map of Ipswich, MA.

- Figure 2. Showing the location of the Ipswich Mills Dam on the 1832 (Anderson) map of Ipswich

- Figure 3. Showing the location of the Ipswich Mills Dam on the 1856 (Walling) detail of Ipswich village.

- Figure 4. Showing the location of the Ipswich Mills Dam on the 1872 (Beers) detail map of Ipswich.

- Figure 5. Ca. 1867 photograph of Ipswich Mills Dam, showing “foot-bridge” and “water-way”, view southwest (stone mill at right) (Waters 1917).

Figure 6. Showing the location of the Ipswich Mills Dam on the 1884 (Walker) detail map of Ipswich. - Figure 7. Showing the location of the Ipswich Mills Dam on the 1887 (Sanborn) map of Ipswich.

Figure 8. Ca. 1896 photograph of the Ipswich Mills dam and wood footbridge, looking south (upstream) towards the dam (courtesy Ipswich Public Library, Ipswich, MA). - Figure 9. Ca.1900 photograph by Arthur Wesley Dow showing the northeast end of the Ipswich Mills Dam and wood footbridge. (https://historicipswich.net).

- Figure 10. Showing the location of the Ipswich Mills Dam on the 1897 (Sanborn) map of Ipswich.

- Figure 11. Showing the location of the Ipswich Mills Dam on the 1916 (Sanborn) map of Ipswich.

- Figure 12. Showing the location of the Ipswich Mills Dam on the 1944 (Sanborn) map of Ipswich.

Statement of Significance

The Ipswich Mills Dam (built 1908) is a run-of-the-river dam at the head of tide on the Ipswich River in downtown Ipswich. Its granite block and concrete spillway extends 132 ft across the river and features a floating log boom. On its east abutment, an abandoned concrete fish ladder constructed in 1919 is adjacent to a functioning concrete denil fish ladder constructed in 1996. A fish viewing platform extends from the east abutment to the fish ladders.

The Ipswich Mills Historic District (IPS.I; NRID 96000923; listed 1996) was listed in the National Register under Criteria A and C as a well-preserved example of a small-scale industrial community that showcases Ipswich’s primary industry during its peak period. The Ipswich Mills Dam is significant as a contributing structure to the Ipswich Mills Historic District for its association with the Ipswich Mills Company and the long history of manufacturing in Ipswich at this location.

The dam is the latest iteration in a succession of dams that were built on the site beginning at least as early as 1637. The original dam provided power for a grist mill operated by Richard Saltonstall (1610–1694). By 1729, the dam at the site was providing power to a nexus of mills in the surrounding area, including a grist mill, a fulling mill, and a sawmill. At the onset of the Industrial Revolution, production at the mills powered by the dam began to shift from small-scale local market production to larger-scale manufacturing for wider markets.

In 1824, Joseph Farley and brothers George Washington Heard and Augustine Heard opened the short-lived Boston & Ipswich Lace Company on the west side of the river. In 1827, the dam was replaced with a higher stone dam, then in the following year, Farley and the Heard brothers incorporated the Ipswich Manufacturing Company, a cotton manufacturing company. The dam was augmented in 1830 with larger flashboards and again in 1845 with the installation of a fish passage.

In 1846, the Ipswich Manufacturing Company was sold to the Dane Manufacturing Company, although Augustine Heard retained ownership of the dam. In 1868, the mill and dam were purchased by Amos A. Laurence (1814–1886). The company was renamed to the Ipswich Mills Company, which produced hosiery and became the largest hosiery mill in the country. The dam was rebuilt as a granite masonry structure by 1880. This iteration of the dam included a distinctive “dog-leg” footprint on the east side of the river.

In 1887, a footbridge was added to its crest that linked the east and west sides of the river. The dam was then rebuilt in 1908 to its current footprint, eliminating the “dog-leg” on the east side of the river and shifting the dam to the north. A fish ladder was added to the east bank in 1919. The dam was only minorly altered through repairs until 1973, when the steel truss footbridge spanning the dam was removed, and the dam’s gate openings were filled with concrete block. A new concrete denil fish ladder was added in 1996.